Many advantages from inclined belt filters

basic technical knowledge

Abwa-Tec inclined belt filters ensure effective filtering of all liquids, prevent operational shut-downs and improve OSHE. In addition they are especially advantageous when treating liquids with a high pollution rate, increasing the economic results. Abwa-tec inclined belt filters are the perfect solution for the following applications:

Benefits for the user

Filtering of coolant lubricants and

emulsionsFiltering of cleansing liquids

Waste water cleaning

Cooling water circulations

Process liquids

Filter reverse rinsing water

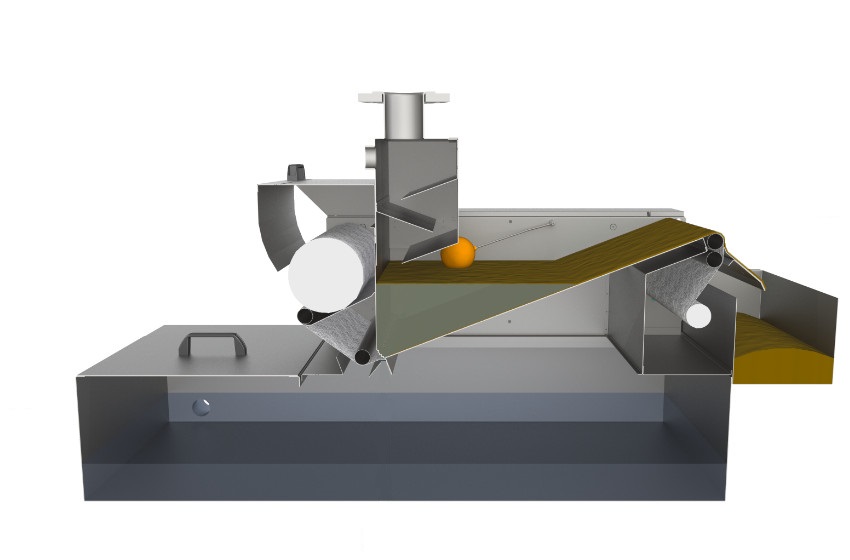

The functioning of the plant

Inclined belt filters are used for filtering liquids by means of a filter fleece. The device is an inclined hydrostatically working filter (above own liquid weight) filtering liquids by means of a filter fleece. The device is a hydrostatic (through the own weight of the liquid) inclined filter, where all parts in contact with the medium are made of stainless steel. The filtering is done by means of a self-sealing filter fleece, adjusted to the respective customized application.

The filter fleece is transported by means of a gear motor and after used wound up. The fleece transport is controlled by means of a float switch and the filter residues are stripped off by means of a waste stripper.

| Applications | Particle / Sludge separation |

| Functional principle | Separation via filter flow |

| Filtrate capacity | up to 20 m³/h |

| Total membrane area | Depending on application |

| Membrane pore size (cut-off) | > 5 µm |

| Electrical power supply | 1,5 – 8 kW |