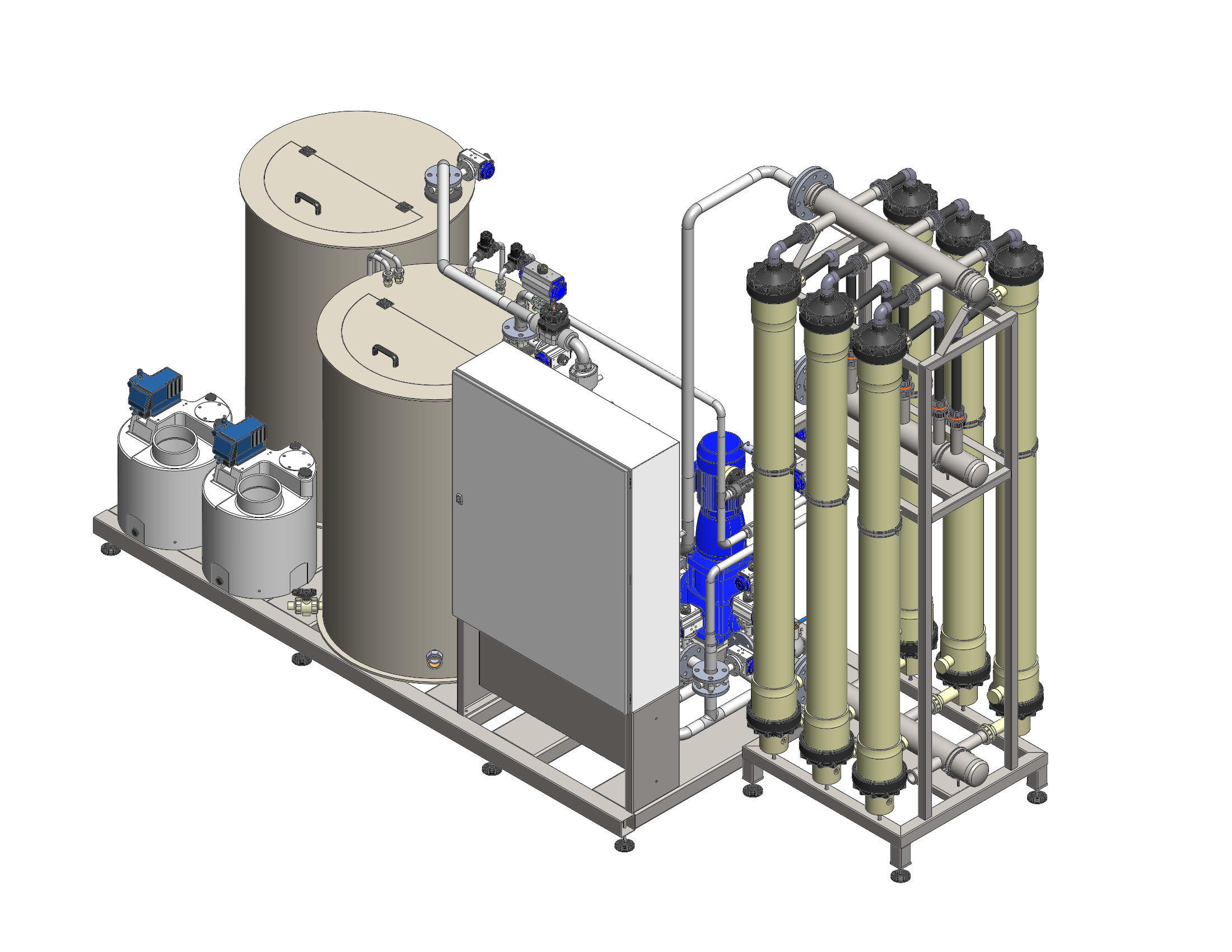

Hollow fiber module systems from Abwa-tec

basic technical knowledge

Abwa-Tec supplies hollow fibre module system, with which large filter surfaces can be combined in a very small space. In hollow fibre modules, also known as capillary modules, so-called capillary membranes are combined to form modules of just a few square millimetres to large filter units of several square metres – saving space and costs!

The functioning of the plant

In capillary modules a bundle of hollow capillaries is inserted in a case and sealed on both ends with curing resin material. The walls of the capillaries are the actual membrane.

In-outside system

The process bath to be treated flows through the capillaries with a high flow velocity and under pressure. The filtrate (permeate) permeates through the membrane, is collected in the case and exits through the filtrate fittings.

Out-inside system

The out-inside system works the other way around: The process bath to be treated is under pressure and flows past the capillaries and through them, so the filtration direction is from outside to inside. The advantage is that a safe operation is also possible with highly polluted process baths (or those with a variety of pollutants).

| Applications | Application for complete removal of solids |

| Functional principle | angential flow filtration, Dead-end filtration |

| Filtrate capacity | 0.1 - 100 m³/h |

| Total membrane area | Depending on application (Polymer membrane) |

| Membrane pore size (cut-off) | Typical0.05 - 0.2 µm |

| Electrical power supply | From 1 kW |