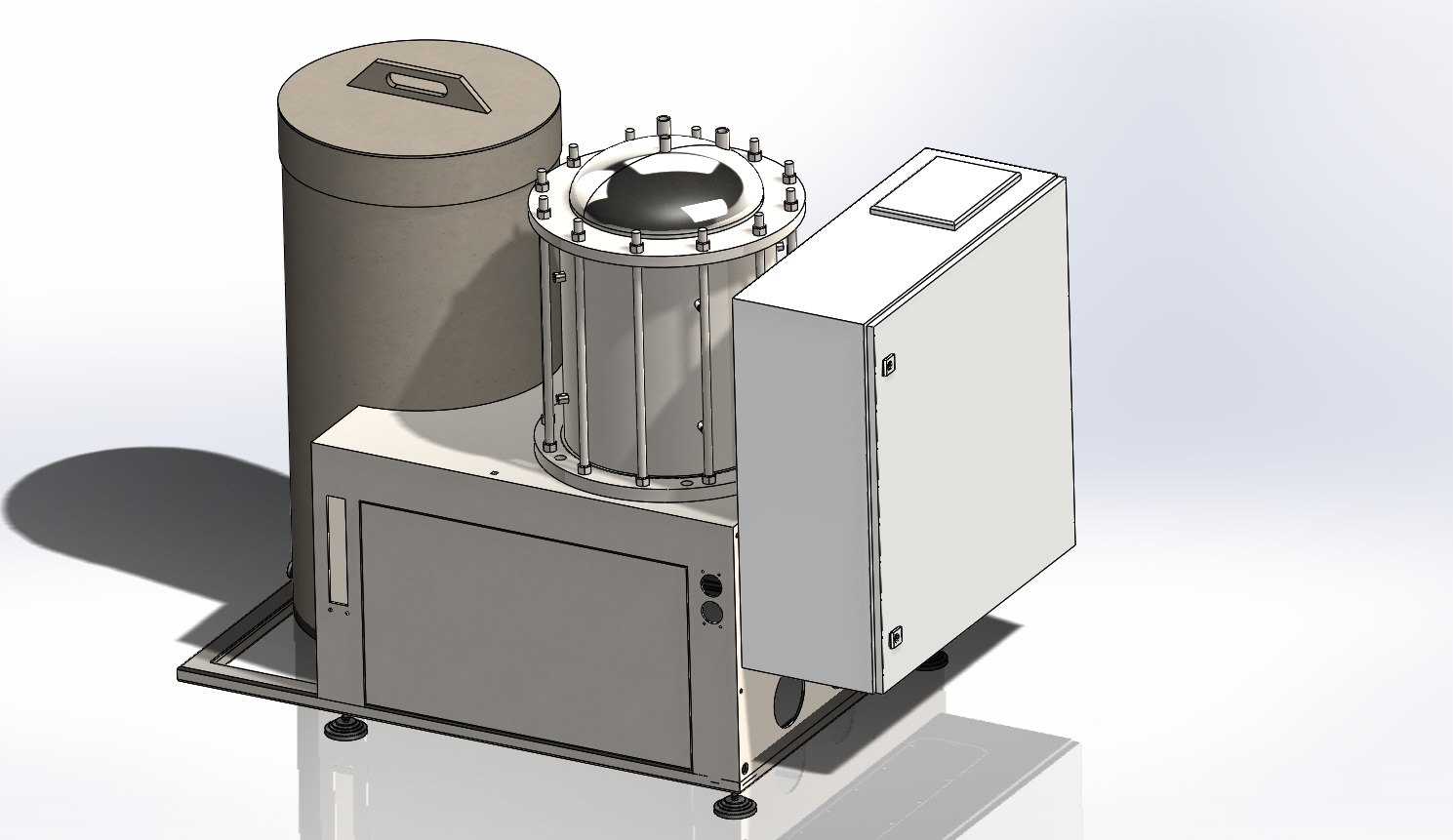

ROTOMEM – The membrane filtration system from Abwa-Tec

basic technical knowledge

With the ROTOMEM filtration system Abwa-Tec has introduced a highly efficient membrane filtration system on the market which requires much less pressure than conventional membrane. Both pressure and cross flow velocity can be adjusted independently, so that circulation pumps that require a high electrical power are no longer necessary.

How the ROTOMEM membrane filtration system works

ROTOMEM membrane filtration systems consist of a cylindrical vessel with the inside walls covered in a membrane and a stirring device. Contrary to conventional membrane technology this system works with a lower pressure. The cross flow over the membrane is created only by means of the special stirring device, which has “wiper-like” blades on the circumference. These blades move across the membrane at a minute distance to the membrane and create the cross flow velocity and turbulence direct on the membrane surface, thus minimizing the cover layer.

This way the process variables pressure and cross flow velocity can be adjusted independently, unlike in conventional cross flow filtration. Heavy duty circulation pumps using a lot of electrical energy are no longer required, which makes the ROTOMEM membrane filtration system a very cost efficient and low maintenance system.

| Applications | Cleaning baths, Degreasing baths, Rinsing baths |

| Functional principle | Rotating filter system |

| Filtrate capacity | Up to 0.8 m³/h |

| Total membrane area | 0,6 / 1,2 / 2,0 |

| Membrane pore size (cut-off) | 0,05 - 0,2 µm |

| Electrical power supply | 1,5 – 3-5 kW |