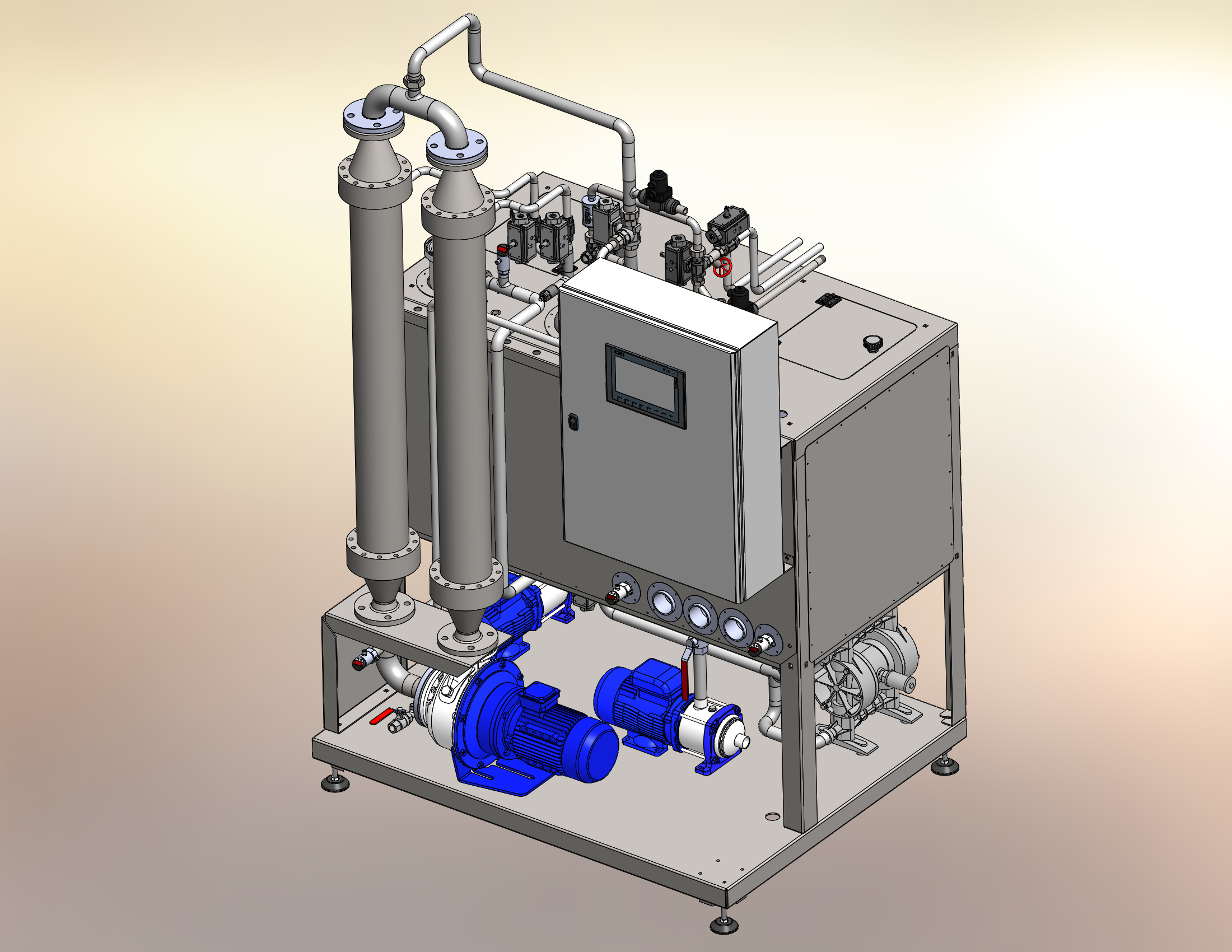

Ultrafiltration plant

basic technical knowledge

The principle of the plant is based on that of membrane separation technology. Here, a microporous membrane separates the medium to be filtered into a retentate and a permeate stream. The permeate (mostly water and dissolved substances and a high proportion of active washing substances) passes through the membrane. The retentate stream contains the components of the substance stream to be separated, which the membrane does not allow to pass due to the separation characteristics (pore size and structure). The driving force that causes this stock stream separation is the applied pressure. The force that prevents a filter cake from building up and only a thin top layer from forming is the flow across the membrane.

The functioning of the plant

The plants are highly effective membrane filtration plants.

The compact design allows it to be used in the smallest of spaces.

Filtration/flow through the filter elements

The filter elements are flown through longitudinally on the inside using the cross-flow principle. Due to the applied internal pressure as the driving force, the liquid, or the low viscosity portion of the liquid mixture, passes through the membrane, flows through the supporting body and is collected in the module housing. From here, the filtrate is then discharged via the filtrate outlet.

The medium flows tangentially to the membrane.

The filtrate passes through the membrane.

The particles are retained at the membrane.

Backwash

Backwashing through the membrane from the outside to the inside. The pressure on the permeate side is higher than on the feed side. The particles are discharged with the feed

Benefits for the user

Environmentally friendly process

Cost-effective operation of the plant by reducing disposal costs

Pre-assembled and functionally tested equipment

Modern control concept with central PLC unit

Compact design

Almost all plants can be extended with additional modules within a series

Almost all plants can be extended with additional modules within a series

Optimum concentration or yield

Low energy consumption

Long process times without cleaning

Easy operation and maintenance

Simple membrane change

| Applications | Communal drinking water treatment, Food- and beverage industry |

| Functional principle | Gross-Flow Filtration |

| Filtrate capacity | 0.1 - 100 m³/h |

| Total membrane area | Depending on application (ceramic) |

| Membrane pore size (cut-off) | 0.05 - 1.0 µm |

| Electrical power supply | From 0.5 kW |