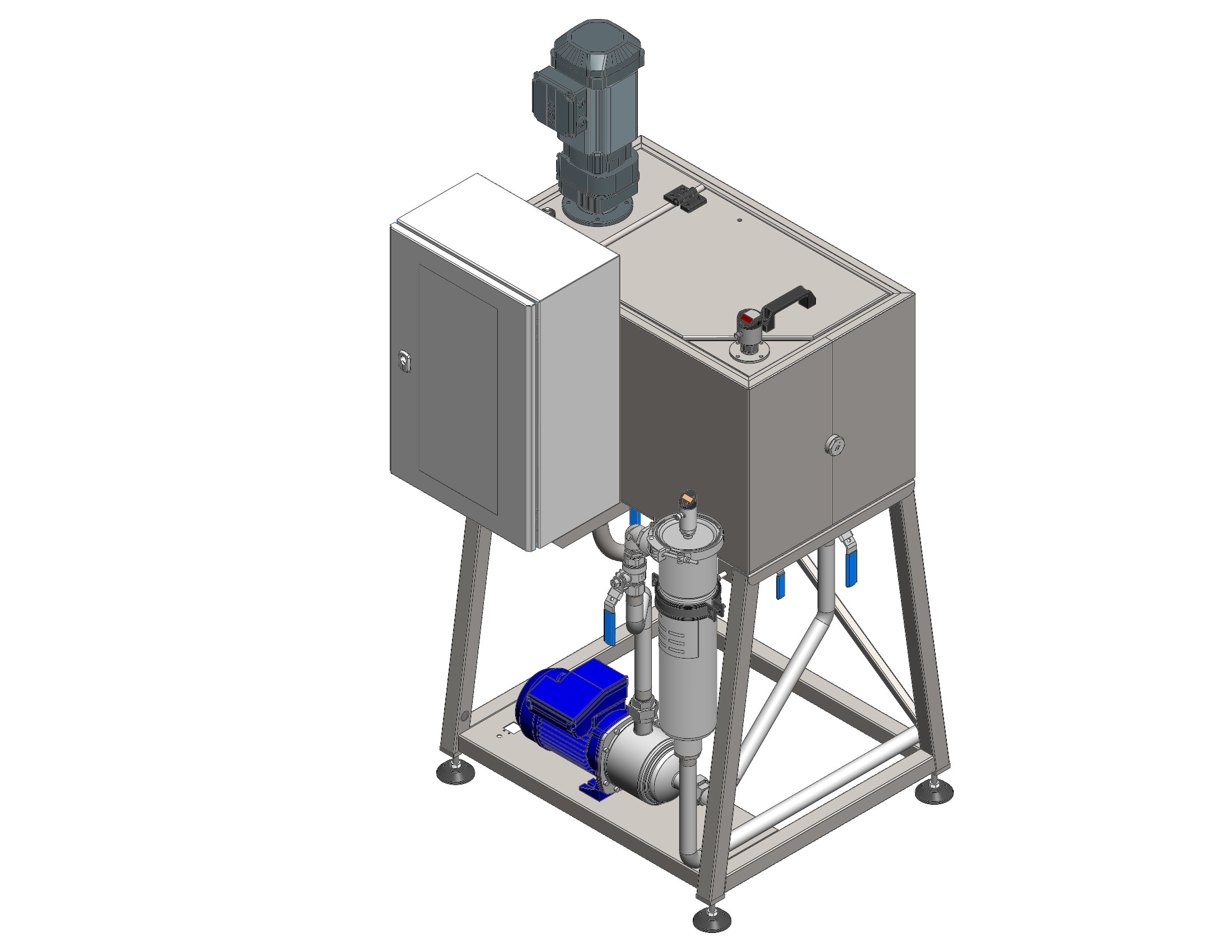

Abwa-Tec gravity separator

basic technical knowledge

The gravity separator is an ecologically high-performance and economical device for cleaning and treating polluted process baths. The retention times of water, cleaning and degreasing baths, also of coolant grease emulsions are extended by means of the gravity separator SKA50.

Other pollutants such as oils, fats, greases etc. are removed from the process bath. By using SKA50 by Abwa-Tec process baths can be retained in the process much longer.

Benefits for the user

Economical

Process baths can be run with the robust and the low-maintenance SKA50 in a circulation. This will guarantee:

continuously excellent quality of the process baths

extension of retention times

savings on cleaner expenses and material expenses

Individual

Upon customer request we can provide customized solutions for any kind of solutions. The special solutions would be:

Plate packs to support coalescence

Bath ventilation for the reduction of bacteria (e.g. KSS), which would support the rise of oil drops and reduce CSB

The functioning of the plant

The SKA PPT works on a physical basis. It uses the effect of gravitation and coalescents for separating alien oils, greases and solids from the process baths.

All with a density difference of more than 5% to water are separated. Lighter substances rise up, other and heavier ones sink. Very small drops gather according to the coalescence principle in clusters and can be separated if the polluted bath liquid rises through arranged trapezoid sheets or by introducing air. This ensures a high efficiency.

By separating the pump from the motor drive, in the gravity separator SKA PPT from the Abwa-Tec group there is no more need for seals being subjected to intensive strains and loads in heavily polluted baths.

| Applications | Grease separators, Coalescence separators, Gasoline separators, Fuel oil barriers |

| Functional principle | Cross-flow separator |

| Filtrate capacity | 0,5 - 20 m³/h |

| Total membrane area | Not applicable (Gravity separation) |

| Membrane pore size (cut-off) | Not applicable (Gravity separation) |

| Electrical power supply | 0,5 kW - 7,5 kW |